This is how we produce it at the farm !

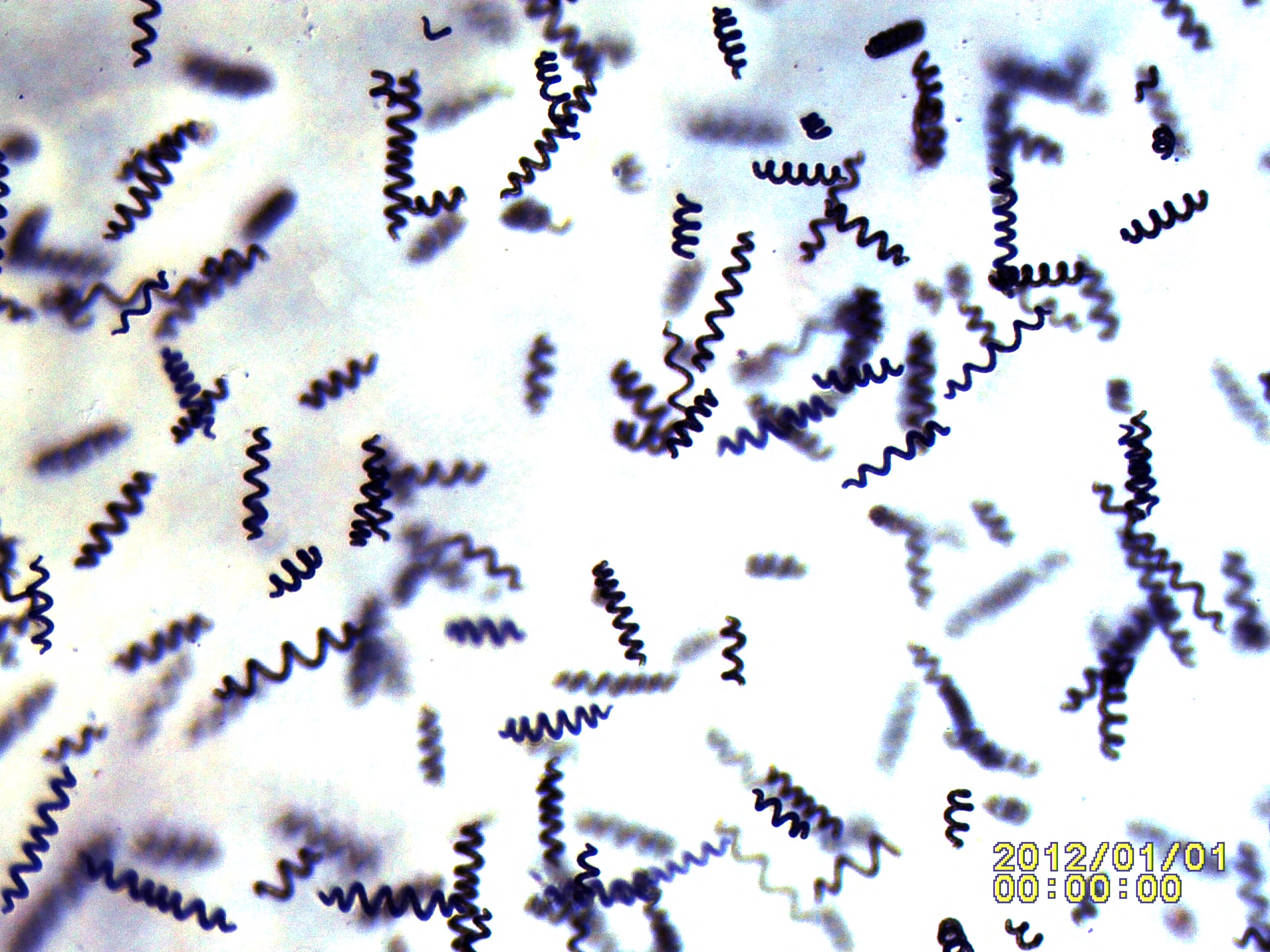

To harvest, the density of spirulina must be sufficient.

During the season it grows quickly and 1 or 2 days pass between each harvest.

When starting a pool this can be more or less rapid

depending on weather conditions and the quantity of seed introduced.

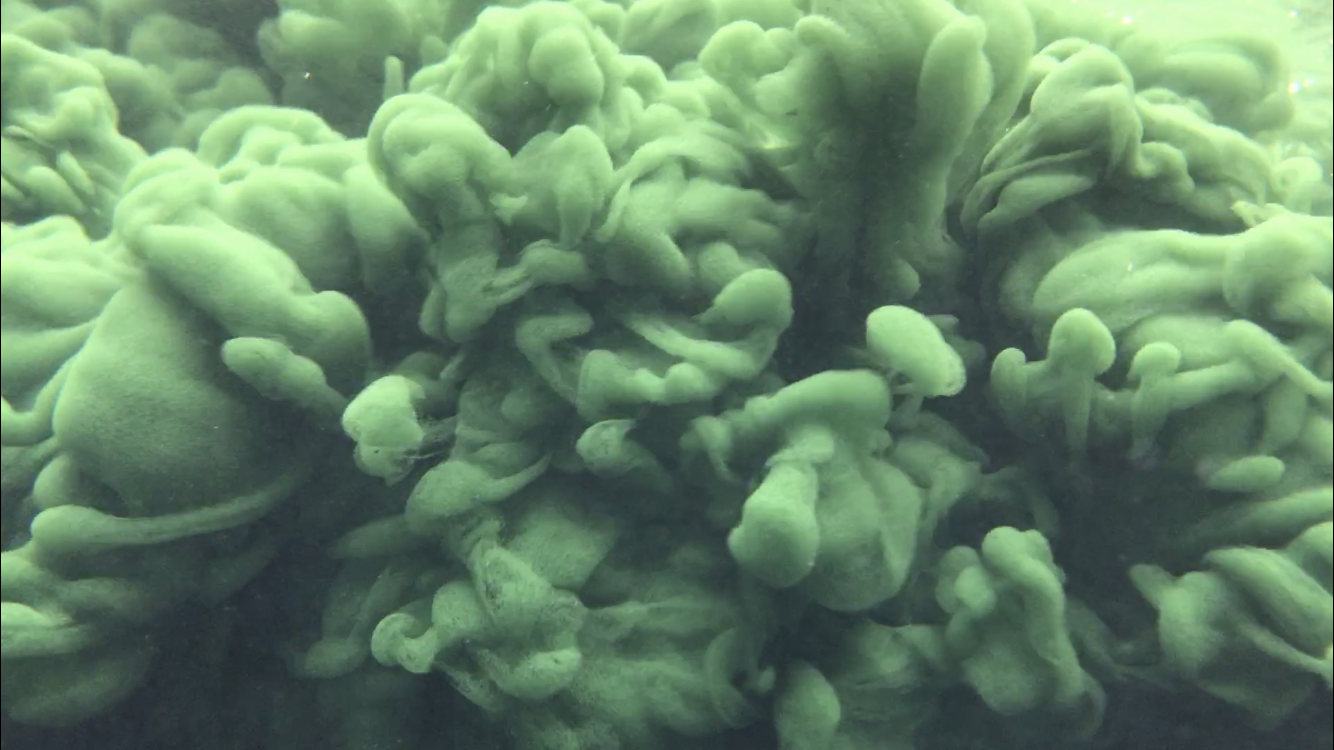

On the left image, spirulina seen under a microscope and on the right an image taken in the pool when the strain was dumped into the pool.

Filtration

In the early morning, spirulina forms a floating layer.

It is pumped and filtered through a canvas,

the culture medium returns to the basin.

As the water flows towards the pool,

spirulina accumulates in the filter.

After gently draining,

it forms a green biomass similar to cottage cheese.

1 liter of spirulina paste will yield approximately 100 g of twigs.

We will now have to collect it and wash the filtration equipment!!

Pressing

The next step will cause the biomass to lose half of its water,

the dough is swaddled in a cloth and put under a press.

This is when we talk about fresh spirulina.

It is then edible, but it cannot be stored for very long.

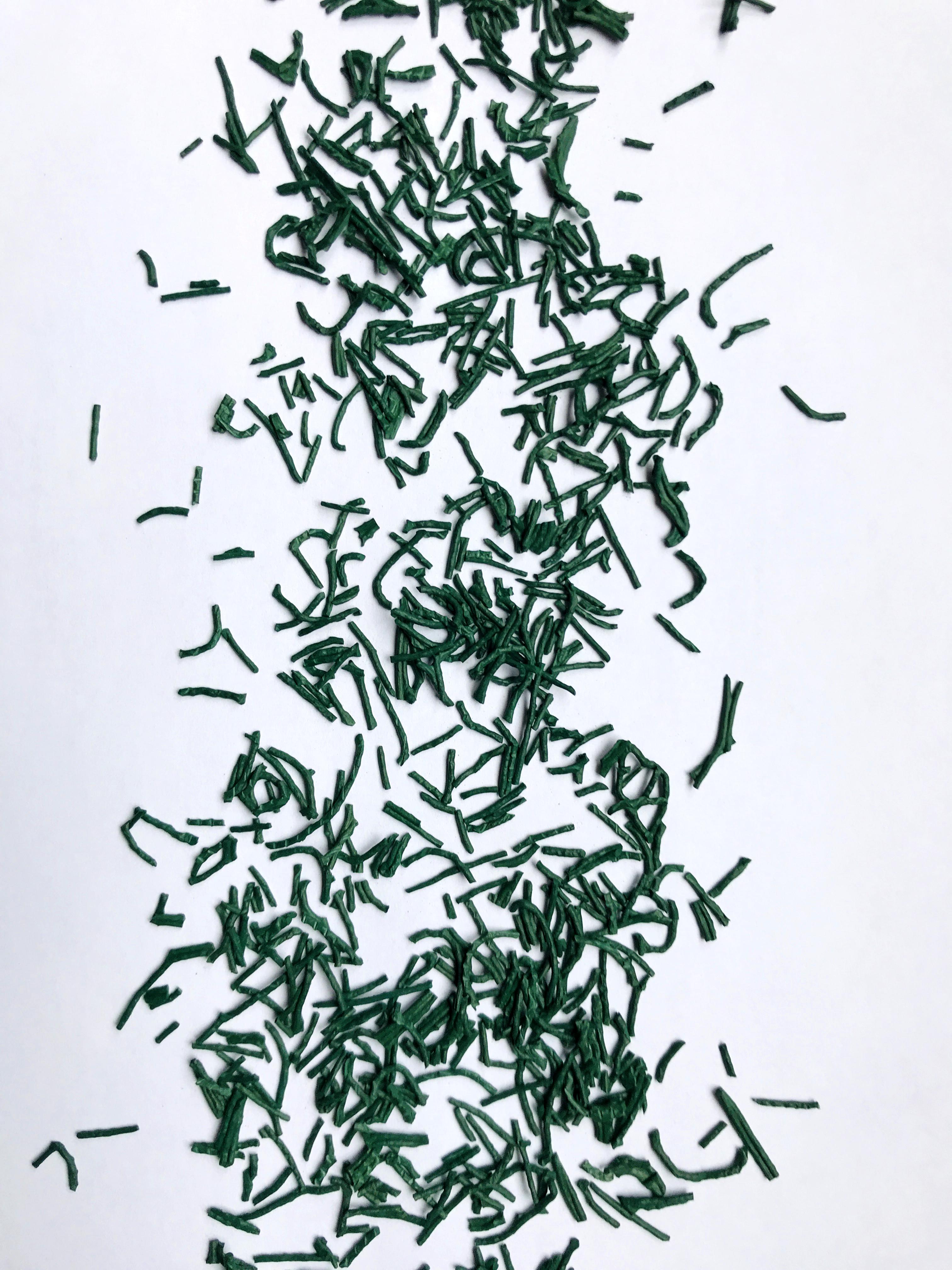

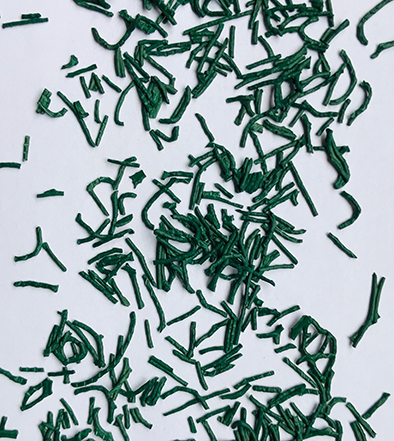

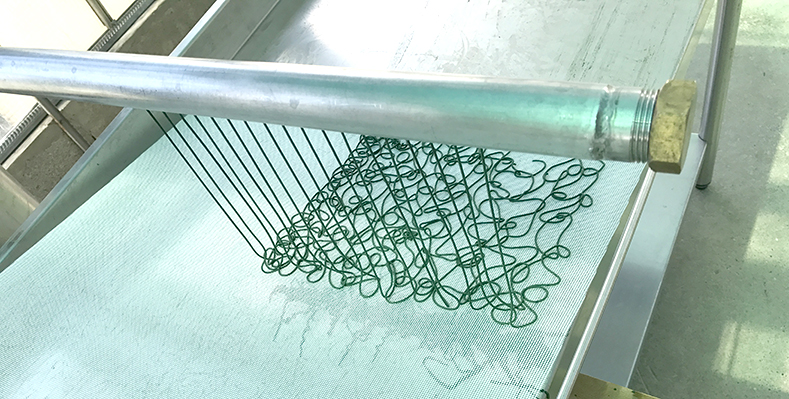

Shaping spirulina spaghetti

and low temperature drying.

This step is to shape it into filaments.

A meat pusher allows you to obtain not sausages

but fine spaghetti with a homemade tool.

These will be able to dry at room temperature.

In this way, spirulina retains all its nutritional value.

Here is the result... fine twigs to sprinkle on your dishes!

A good organic spirulina, soft and crunchy!